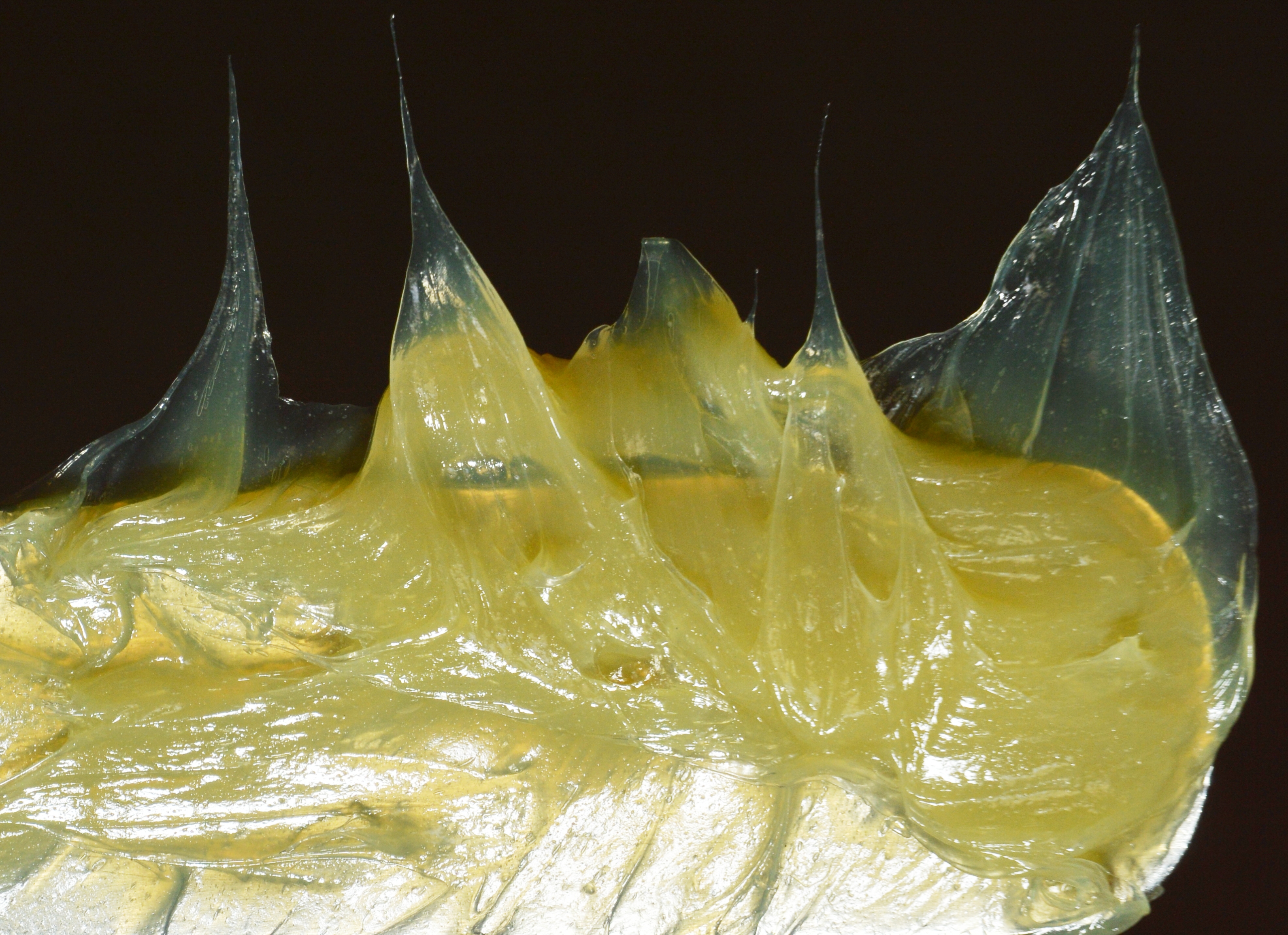

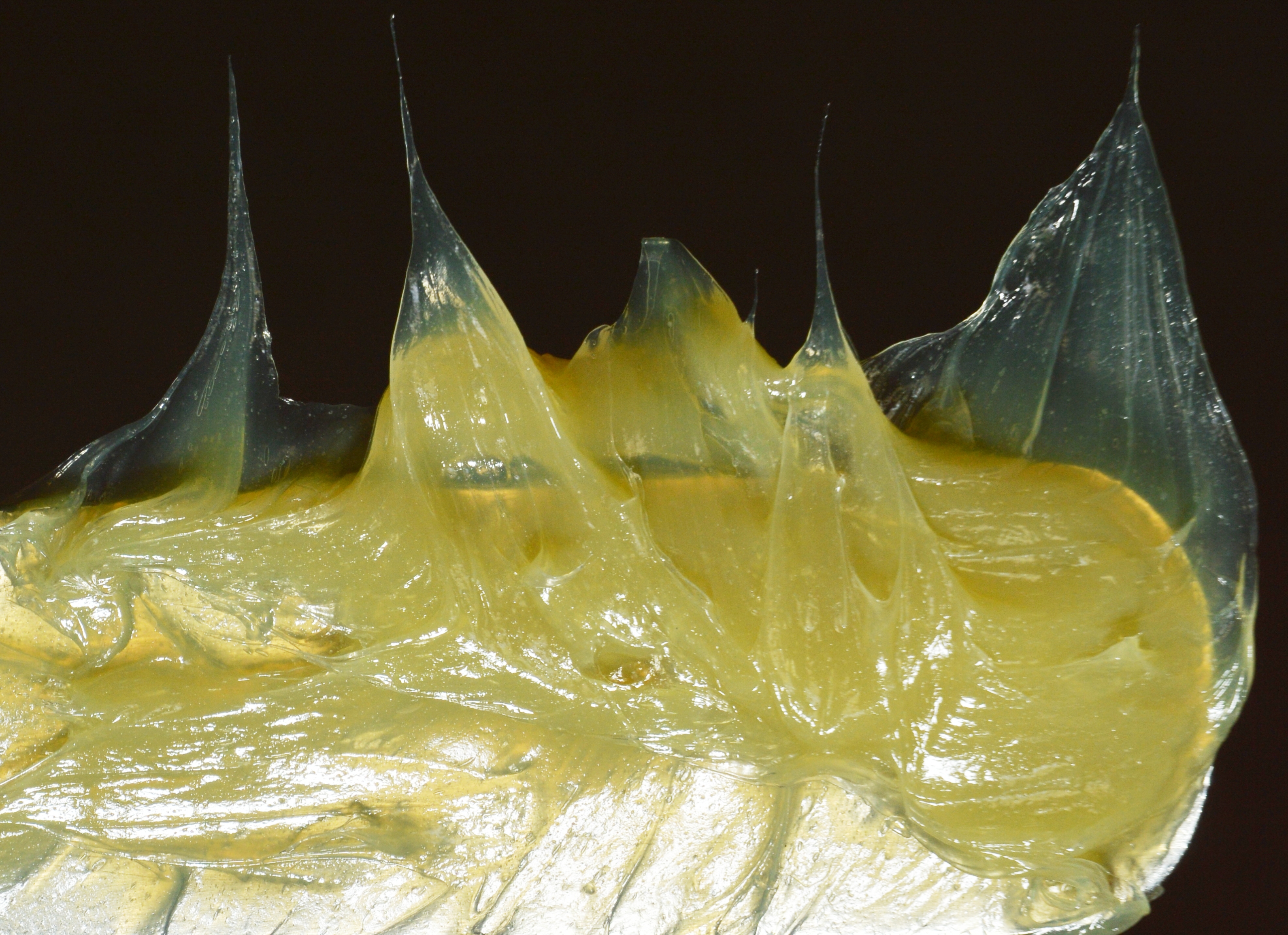

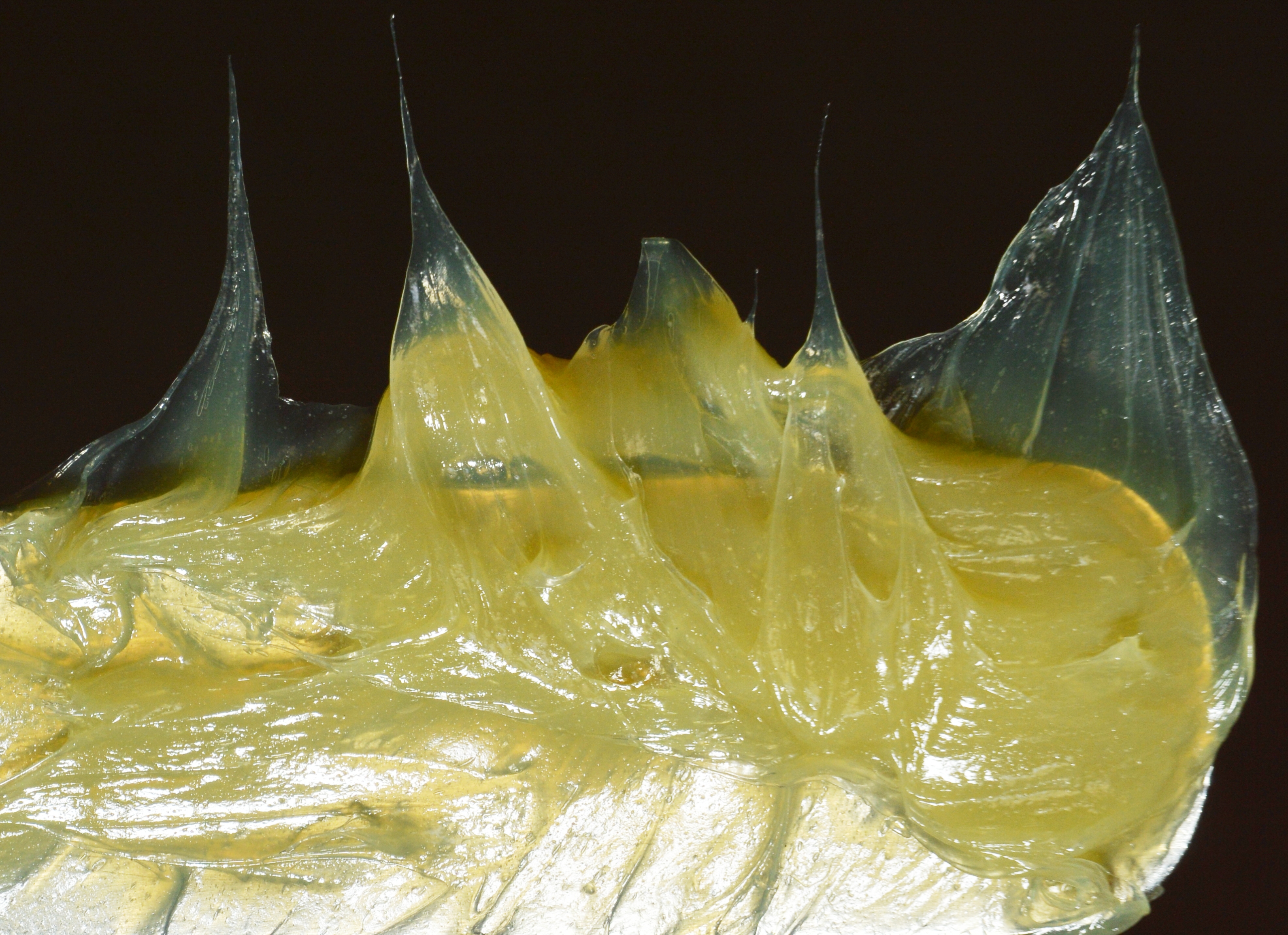

The Importance of Proper Grease

Proper grease application is crucial across various industries and applications, ranging from automotive to manufacturing and beyond. Here are several key reasons why proper grease is important:

1. Friction Reduction:

- Grease is primarily used as a lubricant to reduce friction between moving parts. By properly applying grease, you ensure that the friction between components is minimized, which in turn reduces wear and tear, prolonging the lifespan of the equipment.

2. Wear Protection:

- Grease forms a protective layer between metal surfaces, preventing direct contact and reducing wear. Properly applied grease acts as a barrier against contaminants such as dirt, dust, and moisture, which can accelerate wear and lead to premature equipment failure.

3. Corrosion Prevention:

- Grease helps to inhibit corrosion by sealing out moisture and oxygen, which are primary catalysts for rust formation. By creating a protective barrier, grease safeguards metal surfaces from environmental elements, extending the life of machinery and equipment.

4. Temperature Stability:

- Grease can withstand high temperatures without losing its lubricating properties. Properly selected grease with the appropriate temperature range ensures that machinery operates smoothly even under extreme conditions, preventing overheating and component failure.

5. Sealing Properties:

- Grease can act as a sealant, preventing leaks and contamination. Proper application of grease helps maintain the integrity of seals and gaskets, ensuring that equipment operates efficiently and minimizing the risk of fluid loss or ingress of contaminants.

6. Noise Reduction:

- In addition to lubricating moving parts, grease can also help dampen vibrations and reduce noise levels generated by machinery. Properly lubricated components operate more quietly, creating a safer and more comfortable working environment.

7. Efficiency and Performance:

- Properly lubricated equipment operates more efficiently, requiring less energy and reducing operational costs. By ensuring that machinery is adequately lubricated with the right grease, you optimize performance and productivity while minimizing downtime for maintenance and repairs.

8. Safety:

- Proper grease application is essential for maintaining safe working conditions. Inadequate lubrication can lead to equipment malfunctions, breakdowns, and accidents. By following proper grease application procedures, you help mitigate risks and ensure the safety of personnel and assets.

In summary, the importance of proper grease application cannot be overstated. From reducing friction to choosing the right Grease Manufacturer In India & preventing corrosion and enhancing safety, the right grease, applied correctly, is essential for maintaining the performance, reliability, and longevity of machinery and equipment across various industries.

The Importance of Proper Grease and Lubrication

Proper grease and lubrication play a crucial role in the functioning and longevity of machinery and mechanical systems across various industries. Here are some key reasons why they are important:

1. Reduced Friction:

- Grease and lubricants reduce friction between moving parts in machinery, which helps to minimize wear and tear. This friction reduction is essential for preventing overheating and premature failure of components.

2. Extended Component Life:

- By reducing friction, proper lubrication helps to extend the life of components such as bearings, gears, and shafts. This not only saves on replacement costs but also reduces downtime for maintenance and repairs.

3. Improved Efficiency:

- Well-lubricated machinery operates more efficiently. Reduced friction means less energy is wasted in overcoming resistance, leading to lower energy consumption and increased productivity.

4. Prevention of Corrosion and Rust:

- Grease and lubricants create a protective barrier that helps to prevent corrosion and rust on metal surfaces. This is particularly important in environments with high humidity, exposure to water, or acidic conditions.

5. Noise Reduction:

- Proper lubrication can also help to reduce noise generated by moving parts. This is especially beneficial in environments where noise pollution is a concern, such as factories or residential areas near industrial facilities.

6. Temperature Regulation:

- Lubricants help to dissipate heat generated by friction, contributing to temperature regulation within machinery. This is critical for preventing overheating, which can lead to component failure and safety hazards.

7. Sealing and Contamination Control:

- Grease and lubricants can act as seals, helping to prevent the entry of contaminants such as dust, dirt, and moisture into sensitive components. This is essential for maintaining the cleanliness and reliability of machinery, especially in harsh operating environments.

8. Compliance with Regulations:

- In many industries, proper lubrication is not just a matter of efficiency and performance but also a legal requirement. Failure to adhere to lubrication standards and maintenance schedules can result in fines, penalties, and liability issues.

Overall, proper grease and lubrication are essential for maintaining the performance, reliability, and safety of machinery and mechanical systems. Investing in Best Quality Grease Manufacturer. Grease & Lubrication implementing is a regular maintenance schedule can yield significant cost savings and operational benefits over the long term.

How to Find the Best Greace Manufacturer in India

Finding the best grease manufacturer in India involves a systematic approach to evaluating various factors. Here’s a step-by-step guide to help you identify and select a reliable grease manufacturer:

1. Define Your Requirements:

Clearly define your specific requirements for grease, such as the type (lithium, calcium, etc.), application (automotive, industrial, marine), and performance specifications.

2. Research and List Potential Manufacturers:

Conduct online research and compile a list of potential grease manufacturers in India. Look for companies with a solid reputation and experience in producing the type of grease you need.

3. Check Industry Certifications:

Ensure that the manufacturer holds relevant certifications and complies with industry standards. Look for certifications such as ISO 9001:2015 for quality management systems and other specific certifications related to grease manufacturing.

4. Evaluate Experience and Reputation:

Consider the manufacturer’s experience in the industry. Look for customer reviews, testimonials, and case studies to gauge their reputation. A manufacturer with a good track record is likely to provide quality products.

5. Assess Production Facilities:

Evaluate the manufacturer’s production facilities. Modern and well-maintained facilities are indicative of a commitment to quality. Check if they have the necessary equipment and technology for producing grease to meet your specifications.

6. Review Product Range and Innovation:

Check the manufacturer’s product range and whether they invest in research and development. A manufacturer that stays abreast of industry trends and continuously innovates is more likely to provide high-quality products.

7. Quality Control Measures:

Inquire about the manufacturer’s quality control measures. Ask about their testing processes, quality assurance practices, and adherence to international standards. A reliable manufacturer will have stringent quality control procedures in place.

8. Supply Chain and Distribution Network:

Assess the manufacturer’s supply chain capabilities and distribution network. A well-established supply chain ensures timely delivery of products, minimizing disruptions in your operations.

9. Cost and Pricing Structure:

Obtain detailed quotes from potential manufacturers. While cost is an important factor, it should not be the sole determinant. Consider the overall value, including product quality, reliability, and customer service, when evaluating pricing structures.

10. Customer Support and Service:

Evaluate the manufacturer’s customer support and service. Responsive and reliable customer service can be crucial in addressing any issues or concerns that may arise during the procurement process.

11. Visit the Manufacturer if Possible:

If feasible, consider visiting the manufacturing facilities. This firsthand experience can provide insights into the manufacturer’s capabilities, production processes, and overall commitment to quality.

12. Negotiate Terms and Conditions:

Once you’ve narrowed down your options, negotiate terms and conditions, including payment terms, delivery schedules, and any specific requirements you may have.

By following these steps, you can make an informed decision when selecting a grease manufacturer in India. Always prioritize quality, reliability, and compatibility with your specific needs.

The Major Role of Grease Manufacturer in the Lubrication Industry

Grease manufacturers play a crucial role in the lubrication industry by producing and supplying a variety of greases that are essential for the proper functioning of machinery and equipment. Grease is a semisolid lubricant composed of a base oil, thickener, and additives. It is used to reduce friction, prevent wear, and provide protection against corrosion in a wide range of applications, from automotive and industrial machinery to household appliances. The major roles of grease manufacturers in the lubrication industry include:

1. Formulation and Production:

Grease manufacturers formulate greases by carefully selecting base oils, thickeners, and additives to create a product with specific properties suitable for various applications. The manufacturing process involves blending these components in precise proportions to achieve the desired consistency and performance characteristics.

2. Product Innovation:

As technology advances and industry requirements evolve, grease manufacturers play a key role in developing new formulations and improving existing products. They may invest in research and development to create greases with enhanced properties such as extreme pressure resistance, high-temperature stability, water resistance, and compatibility with different materials.

3. Quality Control:

Grease manufacturers are responsible for maintaining strict quality control standards throughout the production process. This includes testing raw materials, monitoring the manufacturing process, and conducting thorough quality checks on the final product to ensure that it meets industry specifications and performance requirements.

4. Customized Solutions:

Grease manufacturers often work closely with customers to understand their specific lubrication needs and challenges. They may offer customized grease formulations tailored to meet the unique requirements of particular applications, industries, or operating conditions.

5. Supply Chain Management:

Grease manufacturers are involved in managing the supply chain to ensure a steady and reliable distribution of their products. This involves coordinating the sourcing of raw materials, production scheduling, packaging, and timely delivery to distributors, retailers, and end-users.

6. Technical Support:

Grease manufacturers provide technical support to help customers select the most suitable greases for their specific applications. This may involve offering guidance on proper lubrication practices, compatibility with different materials, and troubleshooting lubrication-related issues.

7. Compliance with Regulations:

Grease manufacturers need to adhere to industry standards and regulations governing the production and distribution of lubricants. This includes meeting environmental, health, and safety requirements, as well as complying with specifications set by organizations such as the American Petroleum Institute (API) and the National Lubricating Grease Institute (NLGI).

In summary, grease manufacturers play a vital role in the lubrication industry by developing, producing, and supplying high-quality greases that contribute to the efficient and reliable operation of machinery and equipment across various sectors. Their expertise in formulation, quality control, and technical support helps ensure optimal performance and longevity of lubricated components.

How to Choose Best Engine Oil For Your Vehicles

Choosing the best engine oil for your vehicle is essential to ensure proper lubrication, cooling, and overall engine performance. Here are some steps to help you select the right engine oil:

1. Refer to the Owner’s Manual:

The manufacturer usually provides specifications for the recommended oil type and viscosity. This information is crucial, and deviating from it might affect the engine’s performance.

2. Understand Viscosity Ratings:

Engine oils have viscosity ratings, such as 5W-30 or 10W-40. The first number (e.g., 5W) represents the oil’s viscosity in cold temperatures, while the second number (e.g., 30 or 40) represents viscosity at high temperatures. Consult your owner’s manual to determine the recommended viscosity range for your vehicle.

3. Consider Driving Conditions:

If you regularly drive in extreme conditions (e.g., very hot or cold weather, stop-and-go traffic), you might need oil with specific additives. High-mileage oils are also available for older vehicles with more wear and tear.

4. Check for Certifications:

Look for oil that meets industry standards and has certifications like API (American Petroleum Institute) and ACEA (European Automobile Manufacturers’ Association). These certifications ensure that the oil meets certain performance and quality standards.

5. Synthetic vs. Conventional Oil:

Synthetic oils generally offer better performance in extreme conditions and provide improved protection. However, they can be more expensive. Check your owner’s manual to see if synthetic oil is recommended or required for your vehicle.

6. Brand Reputation:

Stick to reputable brands with a history of producing quality engine oils. You can also check online reviews and recommendations from automotive experts.

7. Oil Change Interval:

Consider the recommended oil change interval for the specific oil you are considering. Some synthetic oils, for example, may allow for longer intervals between oil changes.

8. Vehicle Age and Mileage:

Older vehicles or those with high mileage may benefit from high-mileage oils designed to address issues common in aging engines.

9. Compatibility with Other Fluids:

Ensure that the engine oil you choose is compatible with other fluids in your vehicle, such as coolant.

10. Consult a Professional:

If you’re uncertain or have specific concerns, consult with a professional mechanic for personalized advice based on your vehicle’s needs.

Remember that using the right engine oil is crucial for your vehicle’s longevity and performance. Always follow the manufacturer’s recommendations and consult with professionals if needed.

What is the role and Benefits of Engine Oil?

Engine oil plays a crucial role in the proper functioning and longevity of an internal combustion engine. Here are the primary roles and benefits of engine oils:

1. Reducing Friction:

Engine oil provides a lubricating film between moving parts, such as the pistons, crankshaft, and camshaft, to reduce friction. This helps minimize wear and tear on these components.

2. Heat Reduction:

By reducing friction, engine oil also helps dissipate heat generated during engine operation.

3. Heat Absorption:

Engine oil absorbs heat generated by the engine and carries it away from critical components. It helps in preventing the engine from overheating.

4. Dirt and Deposits Removal:

Engine oil contains detergents and additives that help clean the engine by removing dirt, sludge, and deposits. This prevents the accumulation of harmful substances that can impede engine performance.

5. Sealing Piston Rings:

Engine oil helps form a seal between the piston rings and cylinder walls, preventing combustion gases from leaking into the crankcase.

6. Preventing Rust and Corrosion:

Engine oils often contain additives that protect engine components from rust and corrosion, especially in areas where moisture may accumulate.

7. Contaminant Removal:

Engine oil suspends and carries away particles and contaminants, preventing them from settling in the engine and causing damage.

Benefits of Using Engine Oil:

1. Extended Engine Life:

Proper lubrication and protection against wear and tear contribute to the longevity of the engine.

2. Improved Fuel Efficiency:

Reduced friction and efficient heat dissipation help the engine operate more efficiently, leading to better fuel economy.

3. Enhanced Performance:

Proper lubrication ensures that the engine operates smoothly, contributing to optimal performance.

4. Heat Regulation:

Engine oil helps in managing the heat generated during combustion, preventing the engine from overheating.

5. Reduced Maintenance Costs:

Regular use of high-quality engine oil can lead to fewer engine-related issues, reducing maintenance and repair costs over time.

6. Environmental Impact:

Properly functioning engines, aided by effective engine oil, can produce fewer emissions, contributing to environmental conservation.

It’s important to follow the manufacturer’s recommendations regarding the type and viscosity of engine oil for a specific engine. Regular oil changes are also crucial to maintain the effectiveness of the engine oil and ensure the continued health of the engine.