The Importance of Proper Grease and Lubrication

Proper grease and lubrication play a crucial role in the functioning and longevity of machinery and mechanical systems across various industries. Here are some key reasons why they are important:

1. Reduced Friction:

- Grease and lubricants reduce friction between moving parts in machinery, which helps to minimize wear and tear. This friction reduction is essential for preventing overheating and premature failure of components.

2. Extended Component Life:

- By reducing friction, proper lubrication helps to extend the life of components such as bearings, gears, and shafts. This not only saves on replacement costs but also reduces downtime for maintenance and repairs.

3. Improved Efficiency:

- Well-lubricated machinery operates more efficiently. Reduced friction means less energy is wasted in overcoming resistance, leading to lower energy consumption and increased productivity.

4. Prevention of Corrosion and Rust:

- Grease and lubricants create a protective barrier that helps to prevent corrosion and rust on metal surfaces. This is particularly important in environments with high humidity, exposure to water, or acidic conditions.

5. Noise Reduction:

- Proper lubrication can also help to reduce noise generated by moving parts. This is especially beneficial in environments where noise pollution is a concern, such as factories or residential areas near industrial facilities.

6. Temperature Regulation:

- Lubricants help to dissipate heat generated by friction, contributing to temperature regulation within machinery. This is critical for preventing overheating, which can lead to component failure and safety hazards.

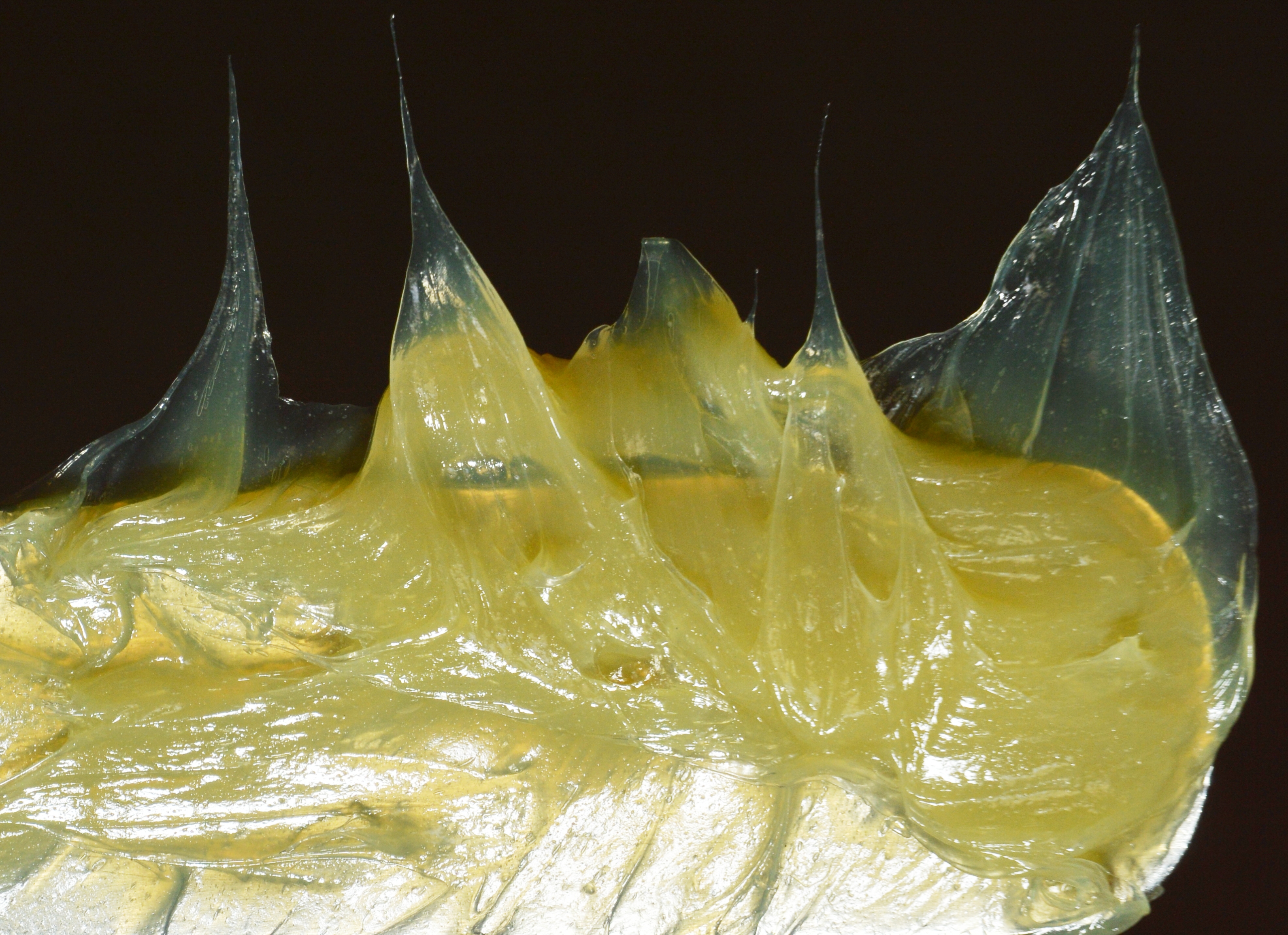

7. Sealing and Contamination Control:

- Grease and lubricants can act as seals, helping to prevent the entry of contaminants such as dust, dirt, and moisture into sensitive components. This is essential for maintaining the cleanliness and reliability of machinery, especially in harsh operating environments.

8. Compliance with Regulations:

- In many industries, proper lubrication is not just a matter of efficiency and performance but also a legal requirement. Failure to adhere to lubrication standards and maintenance schedules can result in fines, penalties, and liability issues.

Overall, proper grease and lubrication are essential for maintaining the performance, reliability, and safety of machinery and mechanical systems. Investing in Best Quality Grease Manufacturer. Grease & Lubrication implementing is a regular maintenance schedule can yield significant cost savings and operational benefits over the long term.

No Comments